Principle, Construction, Working, Uses, Merits and Demerits of Bag Filter

In the pharmaceutical industry, maintaining a clean and safe working environment is crucial for the production of high-quality products. One of the essential tools used for air pollution control and dust collection is the bag filter. Bag filters, also known as fabric filters, are widely used to remove particulate matter from air or gas streams. This process is vital for ensuring the purity and safety of pharmaceutical products. This blog will explore the principle, construction, working, uses, merits, and demerits of the bag filter, providing a comprehensive overview for professionals and enthusiasts in the field.

Principle of Bag Filter

The bag filter operates on the principle of filtration, where air or gas containing particulate matter passes through a fabric filter medium. The primary principles include:

- Filtration Mechanism: Bag filters use fabric or synthetic filter bags as the primary filtering medium. As the air or gas passes through the filter bags, particulate matter is trapped on the surface or within the fabric.

- Reverse Flow Cleaning: In many bag filter systems, a reverse flow of air or gas is periodically introduced to dislodge and remove accumulated particles from the filter bags.

Construction of Bag Filter

The construction of a bag filter typically includes the following components:

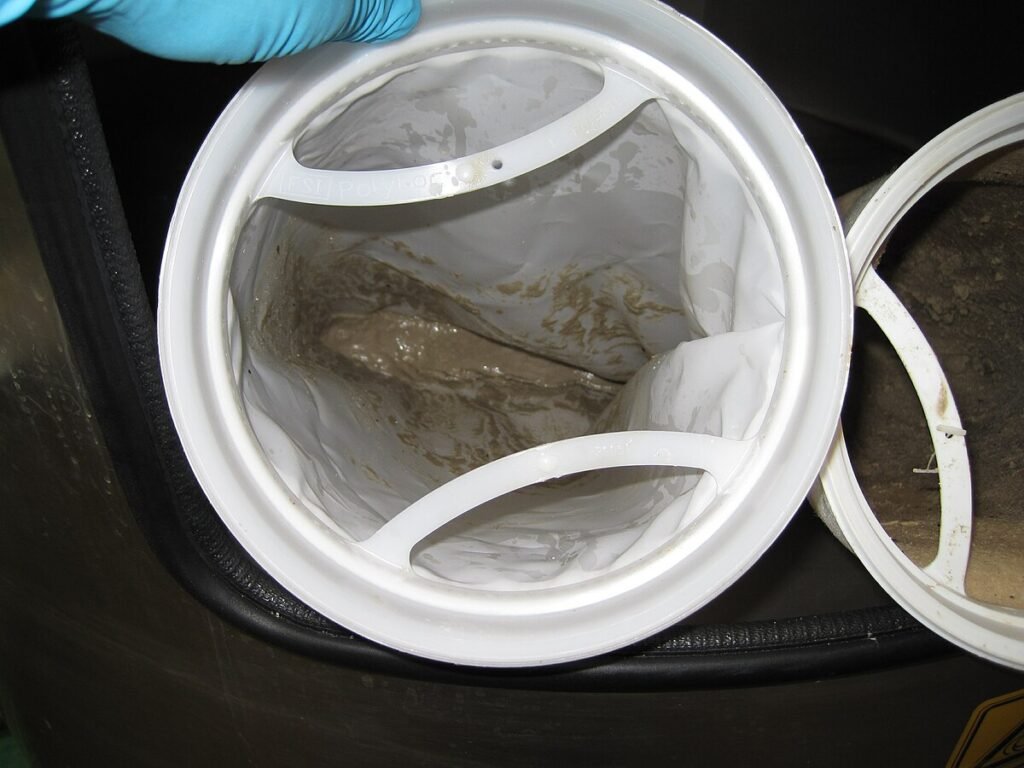

- Filter Bags: Made of various materials, including woven or felted fabric, designed to capture particles of specific sizes.

- Filter Housing: The structure that holds the filter bags and provides the necessary support and sealing.

- Inlet and Outlet Ducts: Allow the entry of polluted air or gas and the exit of cleaned air.

- Cleaning Mechanism: Mechanisms for periodic cleaning, which can include reverse air flow, mechanical shaking, or pulse-jet cleaning.

- Dust Collection Hopper: A collection chamber where dislodged particles are collected for disposal.

Working of Bag Filter

The working process of a bag filter involves the following steps:

- Particle Filtration: Polluted air or gas containing particulate matter enters the bag filter.

- Filtration Process: As the air or gas passes through the filter bags, particles are trapped on the surface or within the fabric.

- Accumulation of Particles: Over time, the filter bags accumulate particulate matter, leading to a decrease in filtration efficiency.

- Cleaning Cycle: Periodically, the cleaning mechanism is activated to dislodge and remove the accumulated particles from the filter bags.

- Disposal: Dislodged particles fall into the dust collection hopper, from where they are removed for disposal.

Uses of Bag Filter

Bag filters are used in various industries, including pharmaceuticals, chemicals, and food processing. In the pharmaceutical industry, they are used for:

- Air Pollution Control: Commonly used in industries to control emissions and comply with environmental regulations.

- Industrial Processes: Employed in various manufacturing processes to capture particulate matter generated during production.

- Power Plants: Used in power plants to control emissions from boilers and other combustion processes.

- Cement and Mining Industry: Applied in cement and mining operations to control dust emissions.

- Woodworking and Metalworking: Used in woodworking and metalworking facilities to capture particulate matter generated during cutting, sanding, or grinding.

Merits of Bag Filter

- Efficient Particle Removal: Effectively captures a wide range of particulate matter, providing high-efficiency particle removal.

- Versatility: Suitable for various industries and applications, offering versatility in controlling different types of particulate emissions.

- Low Operating Costs: Generally has lower operating costs compared to other air pollution control devices.

- Compact Design: Compact footprint, making it suitable for installations where space is limited.

Demerits of Bag Filter

- Maintenance Requirements: Regular maintenance is required to ensure the filter bags remain effective and to prevent clogging.

- Pressure Drop: The accumulation of particulate matter can lead to a pressure drop, which may require additional energy to maintain the desired flow rate.

- Limited Temperature Range: Some filter bag materials may not withstand high temperatures, limiting their use in certain applications.

- Initial Cost: The initial cost of installing a bag filter system can be relatively high, especially for large-scale industrial applications.

Conclusion

The bag filter is an indispensable tool in the pharmaceutical industry, offering efficient and versatile particle removal capabilities. Understanding its principle, construction, working, uses, merits, and demerits is crucial for optimizing its performance and ensuring the production of high-quality pharmaceutical products. By leveraging the benefits of the bag filter while addressing its limitations, pharmaceutical professionals can enhance their manufacturing processes and contribute to the advancement of pharmaceutical sciences.

For more regular updates you can visit our social media accounts,

Instagram: Follow us

Facebook: Follow us

WhatsApp: Join us

Telegram: Join us