Introduction

The basic and initial requirement in pharmaceutical manufacturing industry is the powder. Flow properties of powders affects many common manufacturing problems. Flow properties of powders are basically mechanical property. Powders may be free flowing or sticky. In this article we will see powder characteristics, factors affecting flow properties of powder, methods to determine flow properties of powder and how to improve flow properties of powder.

Powder characteristics

The powder is characterized by following parameters; bulk density, tapped density, true density, porosity and flow behavior.

Bulk density

Bulk density includes the volume of all pores within powder sample. Bulk density is an important parameter in the manufacturing process of tablet or filling of capsule with high dose active ingredient. If drug has low bulk density it has to be aided with excipients. Bulk density is also called as apparent bulk density. It is expressed as g/cm3. It is calculated by the formula:

Bulk density = Weight of powder/ Bulk volume

Tapped density

Tapped density helps to know the compactability of powder while formulating tablet and to select size of capsule for filling of active dose.

Tapped density = Weight of the powder/ Tapped volume

True density

It is defined as the density of powder excluding the volume of pores and voids from powder sample. It used to explain the packability and behavior of powder when used in binary mixtures.

Porosity

Porosity or void fraction is a measurement of void (empty) spaces of powder sample. It is the ratio of volume of voids to the total volume. It ranges between 0 to 1. Porosity is a significant property to decide powder behavior and development of final product. porosity also plays important role in granulation method, disintegration of tablet, dissolution rate, hardness of tablet.

Flow behavior

Flow behavior is characterized by sub parameters like, particle size, shape, density, moisture content etc. Flowability of chemical compound is depend on the habit and internal structure of the compound.

Factors affecting flow properties of powders

- Particle size: Very fine particles have attractive forces like Van Der Waals, surface tension and electrostatics which results in cohesion of powder and poor powder flow properties. If the particle size of powder is increases it also increases flow of powders.

- Density: Density is an important parameter in the manufacturing process of tablet or filling of capsule with high dose active ingredient.

- Particle surface and shape: Smooth surface particles have high flowability and rough surface particles have poor flowability. Flat and elongated particles raise the porosity and has low flow property. High density and low porosity of particles give good flowability to powder.

- Moisture content: If the powder has higher amount of moisture, it increases the risk of cohesion or adhesion.

Importance of Flow Properties Of Powders

The flow properties of powders are incredibly important in various industries, especially in pharmaceuticals, food processing, and materials science. Here are some key reasons why understanding and controlling these properties is crucial:

- Manufacturing Efficiency: Good flow properties ensure that powders move smoothly through machinery, reducing the risk of blockages and downtime. This is essential for maintaining production efficiency and minimizing waste.

- Product Quality: Consistent flow properties help achieve uniform mixing, precise dosing, and accurate filling, which are critical for product quality. Poor flow can lead to variations in weight, content uniformity, and overall product consistency.

- Safety and Compliance: In industries like pharmaceuticals, consistent flow properties are necessary to meet regulatory standards and ensure patient safety. Variations in flow can lead to dosage inaccuracies and potential health risks.

- Cost Savings: By optimizing flow properties, companies can reduce production costs associated with equipment maintenance, product recalls, and batch rejections. Efficient flow also allows for better scalability from small-scale R&D to large-scale manufacturing.

- Innovation and Development: Understanding flow properties can lead to the development of new materials and processes, enabling innovation in product formulation and manufacturing techniques.

In summary, the flow properties of powders play a vital role in ensuring efficient production, high-quality products, regulatory compliance, cost savings, and innovation.

Methods to determine flow properties of powders

- Carr’s compressibility index

- Hausner ratio

- The angle of repose

Carr’s compressibility index

To measure Carr’s compressibility, index a volume of powder is filled into a graduated glass cylinder and repeatedly tapped for a known duration. After tapping the final volume of powder is measured. It is expressed as following ratio:

Carr’s index (%) = (taped density-bulk density/ tapped density) x 100

| Carr’s index (%) | Type of flow | Sample |

| 5-15 | Excellent flow | Free flowing granules |

| 12-16 | Good | Free flowing powdered granules |

| 18-21 | Fair to passable | Powdered granules |

| 23-35 | Poor | Fluid powders |

| 33-38 | Very poor | Fluidized cohesive powders |

| >40 | Extremely poor | Cohesive powders |

Hausner ratio

Hausner ratio is expressed as the ratio of tapped density to the bulk density.

Hausner ratio = tapped density/ poured or bulk density

If the value of Hausner ratio is high it indicates that powder is cohesive in nature and possess poor flow property.

High Hausner ratio or Carr’s index (%) = more cohesiveness and poor flow

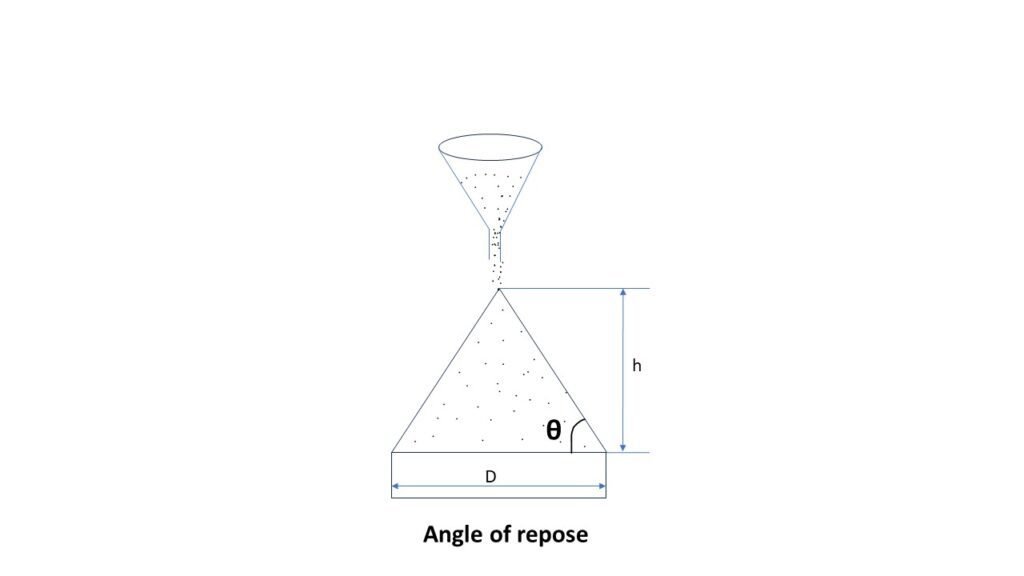

Angle of repose

Angle of repose shows the interparticle cohesion. If cohesion between powder particles is less the flow property of powder is better. Interparticle forces are due to non-specific Van Der Waals forces.

The sample powder is poured onto the horizontal surface and the angle of resulting pile is measured. A greater angle of repose indicates poor flow of powder. It is determined by following equation:

Tan θ = h/r

Where, θ = angle of repose

h = height of pile

r = radius

| Angle of repose (in degrees) | Type of flow |

| 25-30 | Excellent |

| 31-35 | Good |

| 36-40 | Fair |

| 41-45 | Passable |

| 46-55 | Poor |

| 56-65 | Ver poor |

| >65 | Very, very poor |

Methods to determine angle of repose

Static angle of repose

- Fixed-funnel method

- Fixe-cone method

Kinetic or dynamic method

- Rotating cylinder method

- Tilting box method

How to improve flow properties of powders

- Particles size and distribution

- Particles shape and texture

- Surface forces

- Flow activators

Particles size and distribution

Fine particles are more cohesive and has low flowability, hence coarse particles are preferred over the fine particles. Appropriate blend of coarse and fine particles improve the flow properties.

Particles shape and texture

Smooth and spherical shape particle has good flow properties. Rough surfaces, flat and elongated shapes particles have poor flowability. Flow properties of granules can be improved by processing the granules in smooth and spherical shape. Spherical particles can be obtained by spray drying or crystallization.

Surface forces

Moisture content of powder influence the electrostatic charges. Electrostatic charges can be reduced by altering process conditions to reduce frictional contacts. High moisture content of powder increases the risk of cohesion. Drying of powder reduce the moisture content and improve the flow. Hygroscopic particles stored in low humid conditions also helps to control the moisture content.

Flow activators

Flow activators improve floe property by reducing the adhesion and cohesion of particles. They are commonly referred as glidants.

Eg. talc, maize, magnesium stearate.

Conclusion

The flow properties of powders impact processes such as tablet manufacturing, powder blending and packaging. Factors such as particle size, shape and moisture content play crucial role in determining flowability. A good knowledge of flow properties of powder ensures the quality and uniformity of final product.

Frequently asked questions

What is flow property of powder?

Flow property is a mechanical property of powder, also called as flowability. It is defined as the relative movement of particles among neighboring particles or along the surface of container.

What are the methods to determine flow properties of powders?

There are three methods to determine flow properties of powders, as follow:

- Carr’s compressibility index

- Hausner ratio

- The angle of repose

What are the factors affecting the flow properties of powder?

Powder flow is influenced by the particle size, shape, density, size distribution, surface area and moisture content.

How to improve flow properties of powders?

Smooth and spherical shape particle has good flow properties. Hence by altering size and shape of particles help to improve flowability. High moisture content of powder sample also reduces the flow property of powder. By controlling moisture in powder, we can improve flow property of powder.

What is porosity of powder?

Porosity or void fraction is a measurement of void (empty) spaces of powder sample. It is the ratio of volume of voids to the bulk volume.

For more regular updates you can visit our social media accounts,

Instagram: Follow us

Facebook: Follow us

WhatsApp: Join us

Telegram: Join us