Flow Properties Of Powders

Micromeritics, the science of small particles, is a critical aspect of physical pharmacy. It delves into the properties of powdered substances, which directly influence their behavior during formulation, manufacturing, and administration. Among these properties, flow properties are of paramount importance as they determine the ease with which powders can be handled, mixed, and processed. Understanding these flow properties is essential for optimizing drug delivery systems and ensuring product quality and efficacy.

Factors Affecting Powder Flow

Several factors contribute to the flow properties of powders:

Particle Size and Shape

- Particle Size: Smaller particle sizes often lead to poorer flow due to increased interparticle forces. For instance, fine powders of drugs like aspirin can exhibit poor flowability, making them challenging to handle and process.

- Particle Shape: Irregularly shaped particles, such as those of certain metal oxides, can hinder flow due to increased contact points and friction.

Surface Properties

- Surface Energy: High surface energy can lead to strong interparticle forces, resulting in poor flowability.

- Surface Roughness: Rough surfaces can increase friction between particles, impacting flow.

Particle Interactions

- Interparticle Forces: Forces like van der Waals forces and electrostatic forces can significantly influence powder flow. For example, electrostatic charges can cause particles to stick together, leading to poor flowability.

Environmental Factors

- Humidity: High humidity can increase the moisture content of powders, affecting their flowability. Hygroscopic powders, such as those containing certain salts, can become sticky and difficult to handle in humid conditions.

- Temperature: Temperature can influence the viscosity of lubricants and binders, affecting powder flow.

Mechanisms of Powder Flow

Understanding the mechanisms of powder flow is crucial for optimizing processing techniques. The primary mechanisms include:

Shear Flow: This occurs when a force is applied to a powder, causing it to deform and flow. Shear flow is commonly observed in processes like tableting, where pressure is applied to compact powder into tablets.

Bulk Flow: This involves the movement of a large mass of powder, such as during the filling of capsules or the transfer of powder between containers. Bulk flow is influenced by factors like particle size distribution, shape, and interparticle forces.

Measuring Powder Flow Properties

Several techniques are employed to measure powder flow properties:

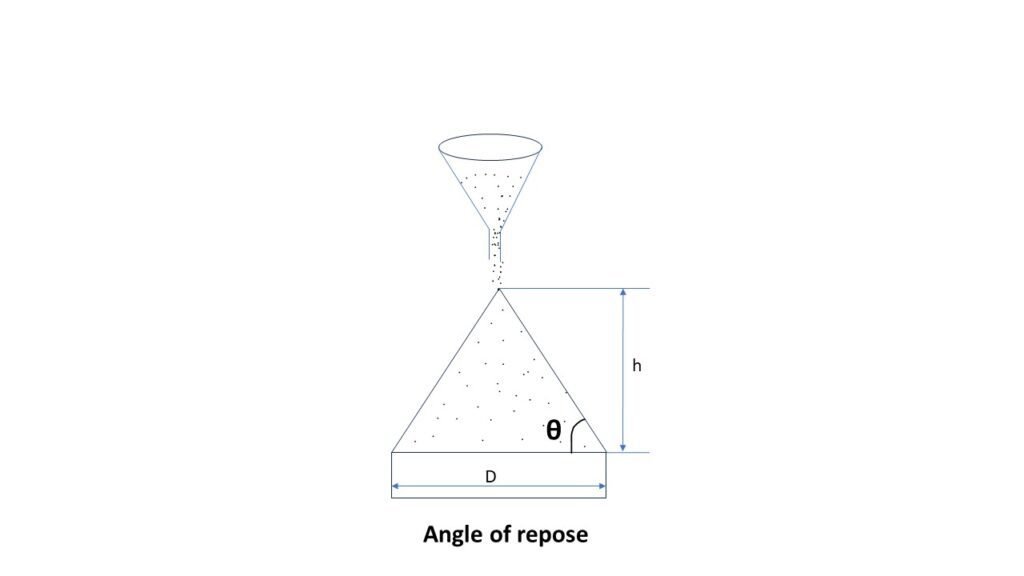

Angle of Repose

- This measures the steepness of a powder cone formed by allowing a powder to flow freely through a funnel onto a flat surface.

- A lower angle of repose indicates better flowability.

Flow Rate Through an Orifice

- The time taken for a fixed amount of powder to flow through an orifice can be measured.

- A faster flow rate indicates better flowability.

Carr Index and Hausner Ratio

- These indices, derived from bulk density and tapped density measurements, provide insights into powder flowability.

- A lower Carr Index and Hausner Ratio indicate better flowability.

Shear Cell Testing

- Shear cell testing involves applying a shear stress to a powder sample and measuring the resulting shear rate.

- This technique can provide information on the rheological properties of powders.

Improving Powder Flow

Various techniques can be employed to improve the flow properties of powders:

Particle Size Modification:

- Milling: Reducing particle size can improve flowability, but excessive milling can lead to increased interparticle forces.

- Granulation: Combining fine particles with a binder to form larger granules can enhance flowability.

Surface Modification:

- Lubrication: Adding lubricants, such as magnesium stearate, can reduce friction between particles.

- Glidants: Glidants, like colloidal silicon dioxide, can improve powder flow by reducing adhesion.

Environmental Control:

- Controlling humidity and temperature can minimize the impact of environmental factors on powder flow.

Mixing Techniques:

- Proper mixing techniques, such as tumble blending or fluid bed blending, can improve powder homogeneity and flowability.

Importance of Flow Properties Of Powders

The flow properties of powders are incredibly important in various industries, especially in pharmaceuticals, food processing, and materials science. Here are some key reasons why understanding and controlling these properties is crucial:

- Manufacturing Efficiency: Good flow properties ensure that powders move smoothly through machinery, reducing the risk of blockages and downtime. This is essential for maintaining production efficiency and minimizing waste.

- Product Quality: Consistent flow properties help achieve uniform mixing, precise dosing, and accurate filling, which are critical for product quality. Poor flow can lead to variations in weight, content uniformity, and overall product consistency.

- Safety and Compliance: In industries like pharmaceuticals, consistent flow properties are necessary to meet regulatory standards and ensure patient safety. Variations in flow can lead to dosage inaccuracies and potential health risks.

- Cost Savings: By optimizing flow properties, companies can reduce production costs associated with equipment maintenance, product recalls, and batch rejections. Efficient flow also allows for better scalability from small-scale R&D to large-scale manufacturing.

- Innovation and Development: Understanding flow properties can lead to the development of new materials and processes, enabling innovation in product formulation and manufacturing techniques.

In summary, the flow properties of powders play a vital role in ensuring efficient production, high-quality products, regulatory compliance, cost savings, and innovation.

Conclusion

Understanding the flow properties of powders is essential for optimizing pharmaceutical processes. By carefully considering factors like particle size, shape, surface properties, and environmental conditions, pharmacists and pharmaceutical scientists can effectively manipulate powder flow properties to achieve desired product performance. By employing appropriate techniques to improve flowability, such as particle size modification, surface modification, and environmental control, the challenges associated with handling and processing powders can be mitigated.

For practice MCQ on this article, click here.

For more regular updates you can visit our social media accounts,

Instagram: Follow us

Facebook: Follow us

WhatsApp: Join us

Telegram: Join us

1 thought on “Flow Properties Of Powders”